What is Leather?

What is Leather?

Leather is a sturdy and versatile cloth that is produced by tanning the rawhide and skins of animals. Cattle hide is the most common raw material. It can be processed on production scales ranging from artisanal to modern manufacturing scales.

Leather is used to manufacture a range of products, including shoes, car seats, garments, belts, book covers, fashion accessories, and furniture. It has a wide range of forms, designs and a wide variety of techniques. The oldest evidence of objects in leather dates back to 2200 BC.

How is The Processes of Production?

The method of leather processing is divided into three basic sub-processes: preparatory steps, tanning, and crusting. In the leather phase series, a further subprocess, finishing, may be inserted, but not all leathers receive finishing.

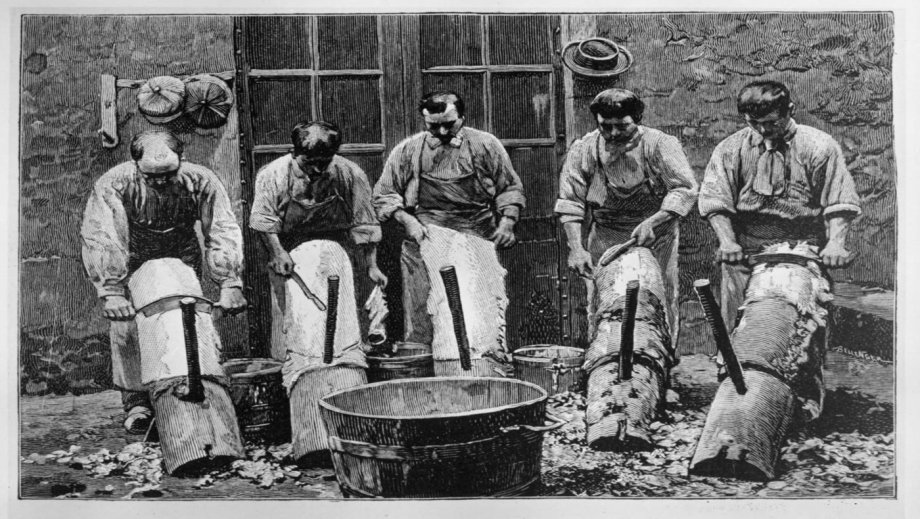

The preliminary stages are the point at which the cover up is ready for tanning. Preliminary stages may incorporate dousing, hair evacuation, liming, deliming, bating, dying, and pickling.

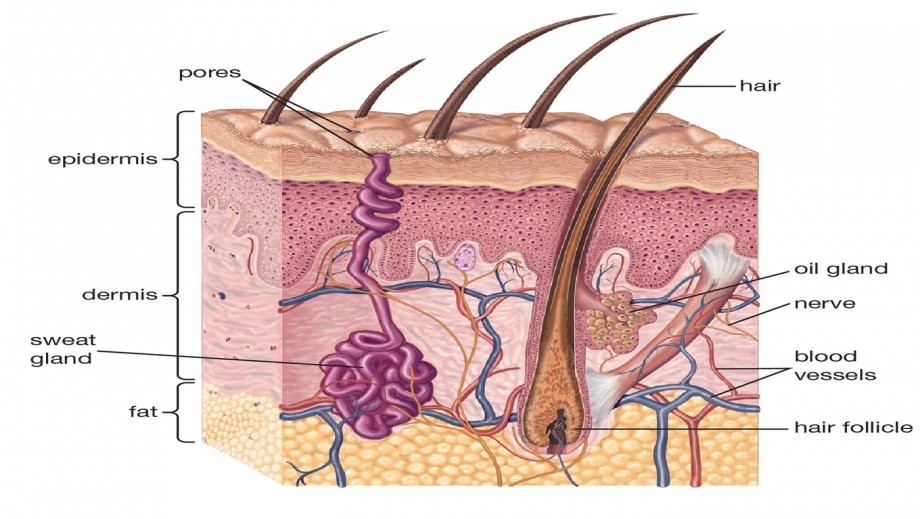

Tanning is a cycle that balances out the proteins, especially collagen, of the crude stow away to build the warm, synthetic and microbiological strength of the covers up and skins, making it appropriate for a wide assortment of end applications. The chief contrast among crude and treated leathers is that crude conceals dry out to frame a hard, unyielding material that, when rewetted, will rot, while tanned material dries to an adaptable structure that doesn't become rotten when rewetted.

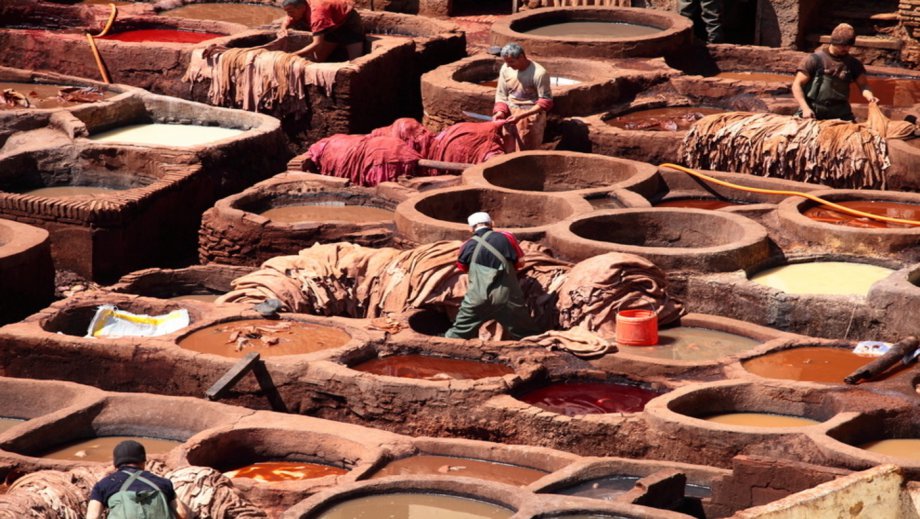

Many tanning techniques and materials exist. The common cycle sees leather experts load the stows away into a drum and submerge them in a tank that contains the tanning "alcohol." The shrouds douse while the drum gradually turns about its pivot, and the tanning alcohol gradually enters through the full thickness of the cover up. When the cycle accomplishes even entrance, laborers gradually raise the alcohol's pH in a cycle called basification, which fixes the tanning material to the calfskin. The all the more tanning material fixed, the higher the calfskin's aqueous steadiness and shrinkage temperature opposition.

Crusting is a cycle that diminishes and greases up cowhide. It regularly incorporates a shading activity. Synthetic compounds added during crusting must be fixed set up. Crusting finishes with a drying and relaxing activity, and may incorporate parting, shaving, coloring, brightening or different techniques.

For certain cowhides, leather experts apply a surface covering, called "wrapping up". Completing tasks can incorporate oiling, brushing, polishing, covering, cleaning, emblazoning, coating, or tumbling, among others.

Cowhide can be oiled to improve its water opposition. This currying cycle subsequent to tanning supplements the regular oils staying in the calfskin itself, which can be cleaned out through rehashed presentation to water. Regular oiling of cowhide, with mink oil, neatsfoot oil, or a comparable material keeps it flexible and improves its life expectancy dramatically.

What is The Tanning Methods?

In tanning methods, the ingredients used in the tanning liquor are largely different. Some forms are common:

Tannins from plant matter such as tree bark prepared for bark mills are tanned using tannins. It's the oldest form known. The paint is smooth and light brown, with exact hue depending on the material blend and skin tone. The colour tan comes from the appearance of tanned vegetable leather.

Vegetable-tanned leather isn't steady in water; it tends to discolor, and in the event that left to soak and after that dry, it recoils and becomes harder, a highlight of vegetable-tanned calfskin that's misused in conventional shoemaking. In hot water, it recoils radically and mostly solidifies, getting to be inflexible and inevitably delicate. Bubbled cowhide is a case of this, where the calfskin has been solidified by being drenched in high temp water, or in bubbled wax or comparative substances. Generally, it was once in a while utilized as covering in the wake of solidifying, and it has additionally been utilized for book authoritative.

Chrome-tanned cowhide is tanned utilizing chromium sulfate and other chromium salts. It is otherwise called "wet blue" for the light blue shade of the undyed calfskin. The chrome tanning strategy for the most part takes roughly one day to finish, making it most appropriate for enormous scope modern use. This is the most well-known strategy in present day use. It is more flexible and malleable than vegetable-tanned cowhide and doesn't stain or lose shape as definitely in water as vegetable-tanned. Nonetheless, there are natural worries with this tanning technique, as chromium is a substantial metal. The strategy was created in the last 50% of the nineteenth century as tanneries needed to discover approaches to accelerate the cycle and to make cowhide more waterproof.

Aldehyde-tanned calfskin is tanned utilizing glutaraldehyde or oxazolidine compounds. It is alluded to as "damp white" due to its pale cream color. It is the most sort of "chrome-free" calfskin, frequently seen in shoes for infants and automobiles. Formaldehyde has been used for tanning within the past; it is being staged out due to threat to specialists and affectability of numerous individuals to formaldehyde.

Chamois calfskin is a type of aldehyde tanning that delivers a permeable and profoundly water-retentive cowhide. Chamois cowhide is made utilizing marine oils (generally cod oil) that oxidize to deliver the aldehydes that tan the calfskin.

Cerebrum tanned calfskins are made by a work concentrated cycle that utilizations emulsified oils, frequently those of creature minds, for example, deer, cows, and bison. They are known for their excellent delicate quality and launderability.

Alum calfskin is changed utilizing aluminum salts blended in with an assortment of folios and protein sources, for example, flour and egg yolk. Alum calfskin isn't really tanned; rather the cycle is classified "tawing", and the subsequent material returns to rawhide whenever absorbed water sufficiently long to eliminate the alum salts.

Grades

In common, calfskin is created within the taking after grades: Top-grain calfskin incorporates the external layer of the stow away, known as the grain, which highlights better, more thickly stuffed filaments, coming about in quality and solidness. Depending on thickness, it may moreover contain a few of the more stringy beneath layer, known as the corium. Sorts of top-grain leather include: Full-grain calfskin contains the whole grain layer, without any evacuation of the surface. Instead of wearing out, it creates a patina amid its valuable lifetime. It is as a rule considered the most elevated quality calfskin. Furniture and footwear are frequently made from full-grain leather. Full-grain leather is ordinarily wrapped up with a dissolvable aniline dye.

Rectified grain calfskin has the surface exposed to completing medicines to make a more uniform appearance. This normally includes polishing or sanding ceaselessly imperfections in the grain, at that point coloring and embellishing the surface.

Nubuck is top-grain cowhide that has been sanded or polished on the grain side to give a slight snooze of short protein filaments, creating a velvet-like surface.

Split cowhide is made from the corium left once the top-grain has been isolated from the cover up, known as the drop split. In thicker covers up, the drop split can be additionally part into a center split and a tissue split.

Bicast calfskin is part cowhide that has a polyurethane or vinyl layer applied to the surface and decorated to give it the presence of a grain. It is marginally stiffer than top-grain cowhide however has a more reliable surface.

Cleft skin contains corium remaining from the top layer of the skin called the bottom layer In thicker skin the gouty cleft can be divided medium and meaty

Bicast leather is split with a layer of polyurethane or vinyl applied to the surface and embossed to give it a texture It's a little more stubborn than Grade I leather but has a more even texture Patent leather is leather that has a shiny finish by adding a coating.

Suede is produced from the underneath of a split to produce a soft, napped finish. It is often made from youthful or smaller species, as the skins of elders often result in a coarse, shaggy sleep.

Current Leather Making

The cutting edge business cowhide making measure includes three fundamental stages: groundwork for tanning, tanning, and handling tanned calfskin. As a fundamental advance, a conceal must be deliberately cleaned and ensured both away and transportation prior to arriving at the tannery. A shroud will start to break down inside hours of a creature's passing; to keep this from occurring, the stow away is restored by a drying out cycle that includes either air-drying, wet or dry salting, or pickling with acids and salts prior to being transported to a tannery.

At the tannery the hide is splashed to evacuate all water-soluble materials and reestablish it to its unique shape and delicateness. Hair is extricated more often than not by a prepare called liming, fulfilled by submerging the covers up in a blend of lime and water; the hair and unessential substance and tissue are evacuated by machine. The cover up is at that point washed, delimed, bated (the enzymatic expulsion of nonfibrous protein to upgrade colour and suppleness), and salted (to supply a last cleansing and softening). The tanning prepare determines its title from tannin (tannic corrosive), the operator that uproots water from the interstices of the hide’s protein strands and cements these filaments together. Vegetable tanning, which is the most seasoned of tanning strategies, is still vital. Extricates are taken from the parts of plants (such as the roots, bark, takes off, and seed husks) that are wealthy in tannin.

The extracted material is processed into tanning liquors, and also the hides are soaked in vats or drums of more and more sturdy liquor till they're sufficiently tanned. the varied vegetable tanning procedures will take weeks or months to complete. the tip result's a firm waterproof animal skin. Mineral tanning, that uses mineral salts, produces a soft, pliable leather and is that the most well-liked technique for manufacturing most light-weight leathers. Use of this method can shorten the tanning amount to days or perhaps hours. metallic element salt is the most generally used mineral agent, however salts from aluminum and zirconium also are used. In mineral tanning the hides are soaked in saline baths of skyrocketing strength or in acidic baths during which chemical reactions deposit salts within the skin fibres. Oil tanning is an previous technique in which animal oil or different oil and fatty substances are stocked, or pounded, into dried hide till they need replaced the natural wet of the initial skin. Oil tanning is employed mainly to create chamois animal skin, a soft porous leather which will be repeatedly wetted and dried while not damage. a good kind of artificial tanning agents (or syntans), derived from phenols and hydrocarbons, also are used.

The pelts are ready to be dried, the final step of the leather production, when the simple tanning process has been completed. The tanned pelts are initially well dried and then threaded to give them the appropriate colour. Drum dyeing, pulverization, brush dyeing and staining are common methods. Mixed oils and greases are then mixed into the leather to improve its softness, resilience and water draining capability.

In the air or in a drying tube, or by first stretching the flesh and then air or tunnel drying, the leather needs to dry to around 14 percent moisture. Paste and vacuum drying are other less commonly used processes. The dried leather is retrofitted to a uniform moisture content of 20 percent, using damp sawdust. It then is extended and softened and covered with the grain surface to add abrasion, split, peeling, water, thermal and cold resistance.

Then the leather is able to be modeled into one of several items. Shoes, caps, exterior clothes, jackets, upholstering leather, suede goods, saddles, gloves, baggage and loads of fun equipment and industrial objects such as buffer rotor wheels and machinery belts are part of this programme.