Production

Kani Leather | Leather Tanning Process | How is Leather Made

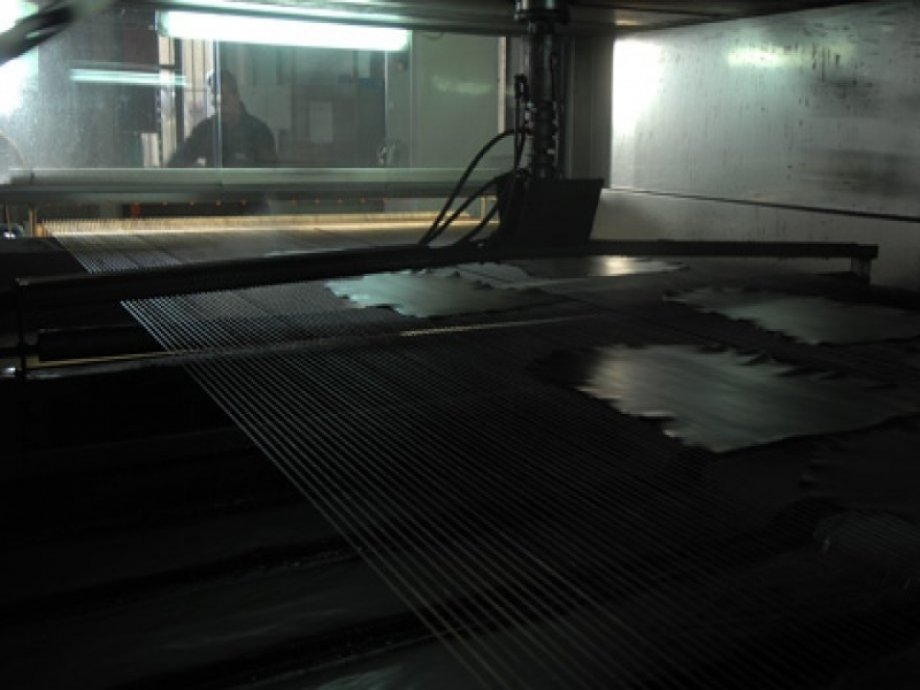

In Kani Leather Tannery, the production cycle of leather tanning is characterized by the integration between traditional techniques and modern technologies. On this page you will find the description of all leather manufacturing phases: tanning, dyeing, finishing and quality control of the leather. After we receive our raw skins, it goes through many stages to keep it. Kani Leather Tannery also meet with our color fans and are offered to your service. In our laboratory, equipped with modern technologies, we test all skins in order to verify that requirements of solidity and environmental protection are met. Kani Leather Tannery embraces a philosophy of quality in leather tanning; hence, important research efforts are made aiming at original effects and make leather an innovating product par excellence. Kani Leather Tannery ensure quality production with it’s innovative quality products and hundreds of references. Kani Leather Tannery imposes rigid standards at the base of its leather production to ensure a higher level of health and safety protection for our employees and places, as well as an incessant commitment to environmental sustainability in the field of water and energy saving for today’s and tomorrow’s citizens. Kani Leather Tannery have obtained the Certification of the SGA Protocol in order to respect the UNI EN ISO 14001: 2004 Environmental Management Guidelines. Through the implementation of the REACH Regulation, Kani Leather Tannery ensure the production of non-toxic skins or concentrations below the allowed limits. Kani Leather Tannery has been awarded ISO 14001 certification for its environmental management system (SGA), showing respect of the environmental legislation requirements in the production cycle. Kani Leather Tannery operates in accordance with the REACH Regulation, which aims to improve the knowledge, dangers and risks arising from the use of chemicals purchased for industrial production. Each product promoted conforms to the ZDHC programme and respects the limits established in the updated List of Restrictive Substances in MRSL production. This programme is designed to eliminate the possibility of using some hazardous chemicals in the global production cycle of textiles, leather and footwear. Quality, research innovation, technological development, attention to the safety of our employees and environment are the indicators that Kani Leather Tannery aims for sustainable business growth to keep up with the demands of the modern market. Kani Leather Tannery has the chance to check the proprieties and tightness of the leather to guarantee specific requirements to the more demanding customers. In addition Kani Leather Tannery use specialized laboratories that perform on our behalf a number of other quality tests.

The following are some of the tests carried out by Kani Leather Tannery:

Xeno test , Bending test, Stretching test, Tearing test, Crocking test, Veslic test, Water drops test, Azo test , And many more